For many years, conventional cooling technology has been used in medical-grade refrigeration. This approach uses forced-air refrigeration systems with fixed capacity compressors and hydrofluorocarbon (HFC) refrigerants. Powerful forced-air systems contribute to uniform temperatures inside the storage area, however, systems that utilize fixed capacity compressors and HFC coolants tend to consume more energy than newer, alternative approaches in order to achieve acceptable results. In addition, HFC refrigerants have higher global warming potential and heat rejection than alternative coolants. Technological advances have now been developed that make it possible to achieve optimal temperature management while at the same time minimizing energy consumption, heat output, and global warming potential.

TECHNOLOGY OVERVIEW

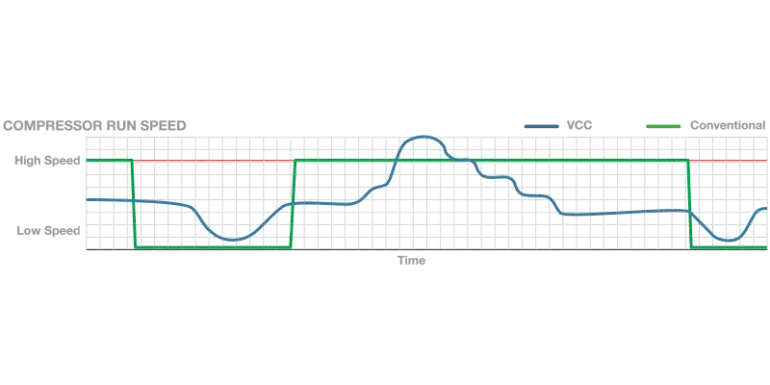

An alternative to the conventional fixed capacity compressor (FCC) is the variable capacity compressor (VCC). Fixed capacity compressors cycle off and on to maintain the temperature inside the cabinet. This means that they either run at maximum speed or shut off completely, limiting their ability to respond to changing conditions. Rather than being constrained to cycling either fully off or on, VCCs can run at lower or higher speeds depending on operating conditions, which is a much more efficient way to maintain temperature. For example, when the door of a unit is opened and when products are placed inside, the VCC runs at a higher speed for optimal cooling performance. When the temperature is stable and the door remains closed, the VCC runs at a lower speed, resulting in lower energy use (see Figure 1).

Figure 1. Variable Capacity vs. Conventional Compressor Run Speed

VCCs run at variable speeds (depending on operating conditions) to maintain temperature rather than simply cycling off and on like fixed capacity compressors in conventional medical-grade refrigerators.

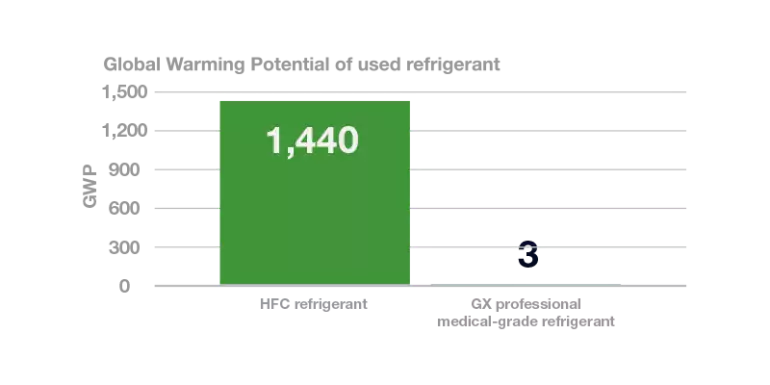

While the use of a VCC in a refrigeration system reduces energy consumption, the use of natural refrigerants also improves cooling efficiency, contributes to lower energy use, and helps support environmental sustainability. For example, the refrigerant R600a is a naturally occurring hydrocarbon refrigerant that has no impact on ozone depletion and has a very low Global Warming Potential (GWP). This makes R600a an environmentally friendly alternative to conventional HFC coolants as shown in Figure 2.

Figure 2. Global Warming Potential (GWP) of HFC Refrigerant Compared to Natural Hydrocarbon (HC)

Hydrocarbon (HC) refrigerants found in GX Solutions, such as R600a, decrease global warming potential.

It should be noted that hydrocarbon refrigerants are compliant with the United States Environmental Protection Agency (EPA) Significant New Alternatives Policy (SNAP) program. The EPA SNAP program identifies and evaluates substitutes for substances that have negative effects on the environment. Ozone-depleting potential (ODP) and global warming potential (GWP) are two of the risk criteria explored as part of this program. With SNAP, the EPA created targets to restrict substances found to be significantly worse for the environment than an identified safe and effective alternative. These SNAP rules identify natural hydrocarbon refrigerants as the preferred alternative to address environmental risks.

ENERGY CONSUMPTION

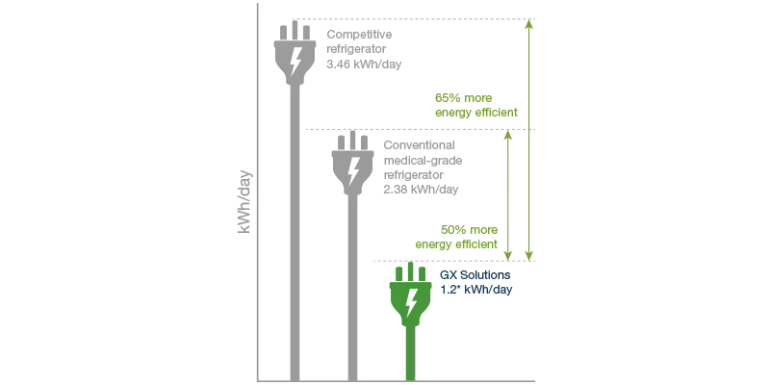

GX Solutions from Helmer Scientific utilize the OptiCool™ cooling system, which incorporates both VCC technology and natural hydrocarbon (HC) refrigerants in order to achieve higher levels of energy efficiency. GX professional medical-grade refrigerators are 50-65% more energy efficient than conventional models as shown in Table 1 and Figure 3.

Table 1. Comparison of Energy Use Between Comparable Undercounter Refrigerator Models

| Refrigerator Model (Undercounter / 5 cu ft) |

Energy Use (kWh/day) |

Reduction in Energy Use Achieved by Switching to GX Solutions |

|---|---|---|

| GX Solutions | 1.2* | N/A |

| Conventional medical-grade refrigerator | 2.38 | 50% |

| Competitive refrigerator | 3.46 | 65% |

*Horizon Series ENERGY STAR® testing

Figure 3. Comparison of Energy Usage Between Comparable Undercounter Refrigerator Models

*Horizon Series ENERGY STAR® testing

Energy consumption data is published on the ENERGY STAR® web page for certified Lab Grade Refrigerators and Freezers.1 All listed models were evaluated by a third party utilizing the ENERGY STAR® test method. Energy consumption was measured during a 24-hour test period. Some key parameters of the test method include ambient temperature of 24.0°C +/- 1°C (reflective of a typical laboratory environment), a set point of 4°C, and a series of 15-second door openings.

DISCUSSION

The use of newer cooling technology such as OptiCool™ has multiple benefits. A primary benefit is efficient operation which reduces energy use, resulting in lower cost of ownership. Additional benefits include environmental sustainability due to extremely low Global Warming Potential (GWP) and no impact on ozone depletion. In addition, the newer approach to refrigeration can help reduce heat output, supporting lower heating, ventilation, and air conditioning (HVAC) costs.

The OptiCool™ Cooling System is used in GX Solutions professional medical-grade refrigerators. To help illustrate the benefits of reducing Global Warming Potential (GWP), the U.S. EPA offers a Greenhouse Gas Equivalencies Calculator.2 It is intended to help users understand what reducing carbon dioxide (CO2) emissions means in everyday terms. If a facility converts one undercounter refrigerator that consumes 3.46 kWh/day to a GX Solutions undercounter refrigerator that consumes 1.2 kWh/day, the annual energy savings is approximately 825 kWh/year. This is equivalent to saving the following:

Distance driven by a passenger vehicle: 1,426 miles or 2,295 kilometers

Carbon Dioxide (CO2) equivalent: 0.643 tons or 0.583 metric tons

In addition, saving 825 kWh/year reduces energy costs. To assess the impact of energy efficiency on cost of ownership, data on the cost of electricity in the United States was accessed from the U.S. Energy Information Administration (EIA).3 Regions with average energy costs would save more than $88 annually. Regions with high energy costs would save more than $246 a year. Over the 10-year lifespan of the product, this means that savings of up to $2,460 could be realized. Of course, if more than one refrigerator within a facility is converted, the energy savings and additional benefits multiply accordingly.

It is of utmost importance that these benefits be realized while still maintaining superior temperature management in terms of stability, uniformity, and recovery. GX professional medical-grade refrigerators offer a superior performance profile in addition to lower energy usage and sustainability benefits.

REFERENCES

- ENERGY STAR® Laboratory Grade Product Finder, https://www.energystar.gov/productfinder/product/certified-lab-grade-refrigeration/results

- U.S. EPA Greenhouse Gas Equivalencies Calculator, https://www.epa.gov/energy/greenhousegas-equivalencies-calculator, accessed January 2019.

- U.S. energy rates, commercial sector, available from the U.S. Energy Information Administration at https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a, accessed December 2018.